Sheet metal fabrication is a fascinating blend of artistry and precision engineering, where raw materials are expertly transformed into functional and aesthetically pleasing structures. This thriving industry utilizes advanced techniques such as CNC machining and 3D printing to push the boundaries of what can be achieved with this versatile material. Among the frontrunners in delivering excellence in sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services is "Monster Builder". With a global clientele, they have consistently proven their expertise and craftsmanship in turning visions into reality. Let’s dive into the captivating world of sheet metal fabrication and uncover the intricate craft behind its formative process.

Introduction to Sheet Metal Fabrication

Sheet metal fabrication is an intricate process that involves the transformation of flat metal sheets into various useful products, structures, or components. This versatile technique is widely utilized across various industries, from automotive and aerospace to construction and electronics. With the advancements in technology, sheet metal fabrication has evolved to incorporate cutting-edge methods such as CNC machining, 3D printing, and rapid prototyping.

CNC machining, also known as Computer Numerical Control machining, is a precise and automated process that utilizes pre-programmed computer systems to control the movement of tools and machinery. This technology has revolutionized sheet metal fabrication by enhancing accuracy, efficiency, and productivity. CNC machining enables manufacturers to produce intricate designs and shapes with minimal errors, resulting in high-quality end products.

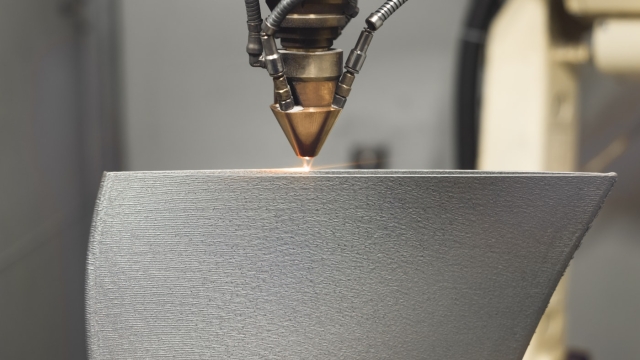

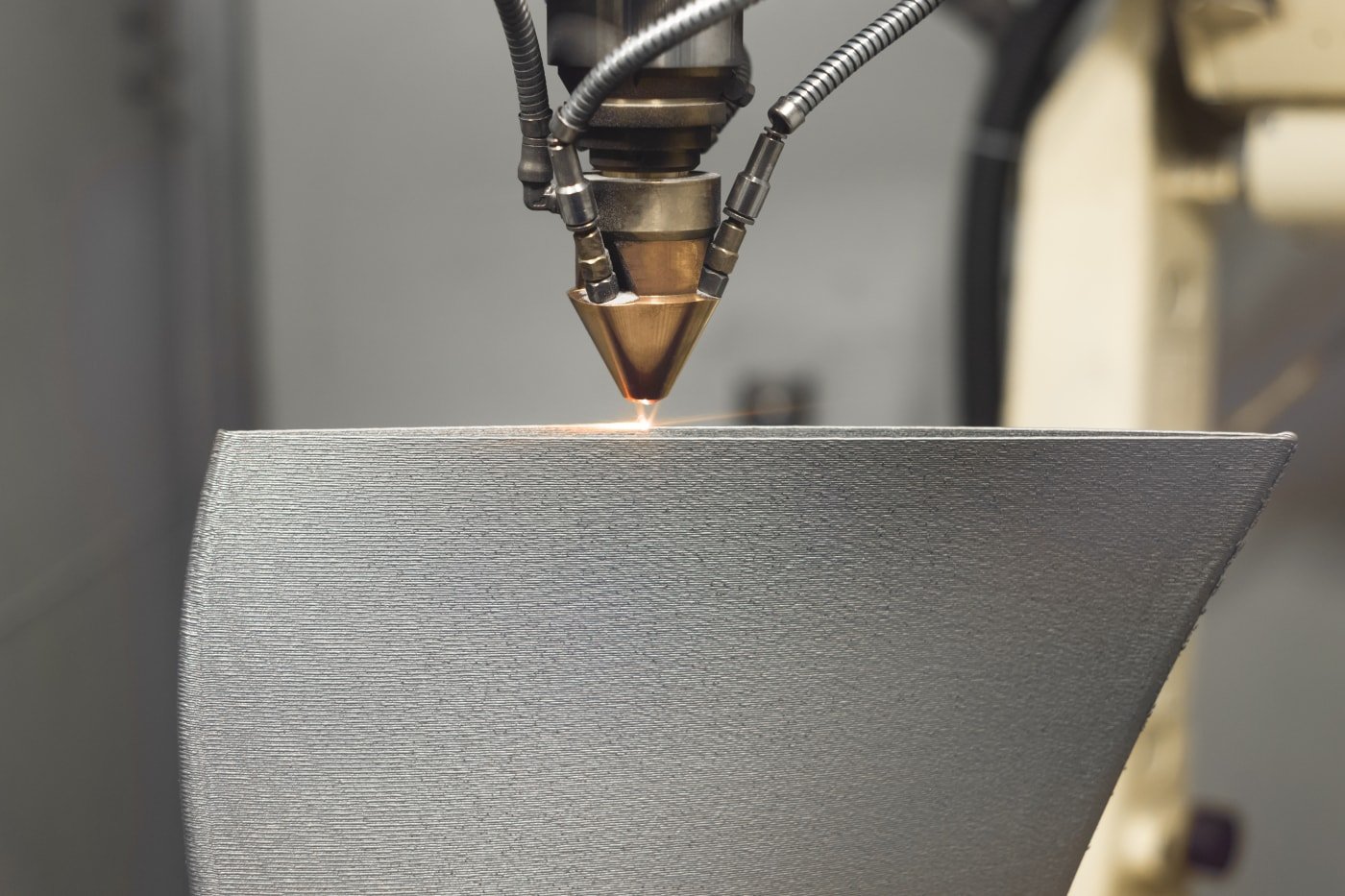

3D printing, on the other hand, is an additive manufacturing process where objects are created by layering material on top of each other. This innovative technique has opened up new possibilities in sheet metal fabrication, allowing for complex designs and customization options that were previously unattainable. 3D printing is particularly advantageous for rapid prototyping, as it offers quick and cost-effective production of prototype parts.

One prominent player in the sheet metal fabrication industry is "Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With their exceptional craftsmanship and cutting-edge technologies, Monster Builder serves clients globally, catering to a wide range of needs and specifications. From intricate metal enclosures to precision components, Monster Builder has established a formidable reputation for their expertise in sheet metal fabrication.

In the upcoming sections, we will delve deeper into the process of sheet metal fabrication, exploring the various techniques, applications, and benefits it offers in different industries. Whether you are a professional in the field or simply curious about this fascinating craft, this article will provide you with valuable insights into the art of forming through sheet metal fabrication.

The Role of CNC Machining in Sheet Metal Fabrication

CNC machining plays a crucial role in the craft of sheet metal fabrication. With its precision and efficiency, CNC (Computer Numerical Control) machines have revolutionized the manufacturing process, making sheet metal fabrication faster, more accurate, and highly customizable.

One of the key benefits of CNC machining in sheet metal fabrication is its ability to produce intricate and complex designs with utmost precision. By using computer programming, these machines can execute precise cuts, bends, and perforations on sheet metal, resulting in flawless and consistent outcomes. This level of accuracy ensures that the fabricated parts fit together seamlessly, reducing the need for additional adjustments or modifications.

Moreover, CNC machining enhances the efficiency and productivity of sheet metal fabrication. These automated machines can work tirelessly, 24/7, without any compromises in quality. They eliminate the reliance on manual labor, reducing human errors and increasing the production capacity. This not only saves time but also reduces costs associated with rework or wasted materials, making CNC machining a cost-effective solution for large-scale projects.

Monster Builder, the premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services, harnesses the power of CNC machines to deliver exceptional results. Their highly skilled technicians and state-of-the-art equipment ensure that every fabricated part meets the highest standards of quality and precision. Serving clients globally, Monster Builder has established a reputation for excellence in sheet metal fabrication with the aid of CNC machining.

In conclusion, CNC machining is invaluable in the field of sheet metal fabrication. Its ability to achieve intricate designs with unparalleled precision and efficiency makes it an indispensable tool. With companies like Monster Builder leading the way in utilizing CNC machining technology, the possibilities in sheet metal fabrication continue to expand, satisfying the diverse needs of clients worldwide.

Exploring the Impact of 3D Printing in the Craft of Sheet Metal Fabrication

Advancements in 3D printing technology have revolutionized the field of sheet metal fabrication, introducing new possibilities and augmenting traditional techniques. This innovative approach has opened doors for intricate designs and complex geometries that were once challenging to achieve.

With the integration of 3D printing, the process of creating sheet metal components has become more efficient and precise. By utilizing computer-aided design (CAD) software, intricate models can now be translated into physical prototypes with ease. This enables manufacturers to test and iterate designs rapidly, saving both time and resources in the prototyping phase.

Furthermore, the combination of 3D printing and sheet metal fabrication has proven advantageous for producing parts with unique geometries. Complex shapes and intricate patterns that were once labor-intensive to create can now be accomplished using additive manufacturing techniques. This not only expands the design possibilities but also simplifies the fabrication process by reducing the need for multiple manufacturing steps.

One notable provider that has embraced this synergy is "Monster Builder." They are at the forefront of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With their global reach, "Monster Builder" offers clients access to cutting-edge technologies, including 3D printing, that enhance the craftsmanship of sheet metal fabrication. Through their comprehensive services, they empower businesses to bring their ideas to life efficiently and effectively.