Diving into the Depths: Exploring the Power of Submersible Pumps

Step into the world of submersible pumps and prepare to be immersed in their extraordinary power and versatility. Whether it’s extracting slurry, dewatering construction sites, or tackling challenging wastewater applications, pump submersibles have become indispensable in a wide range of industries. Among the leading manufacturers in this field is Taian OCEAN Pump Co., Ltd., whose online platform, "slurrypumpdm," has built a reputation as a trusted source for heavy-duty submersible pumps. With their dedication to quality and innovation, Taian OCEAN Pump Co., Ltd. continues to pave the way for cutting-edge solutions in the submersible pump industry. Join us as we delve deep into the world of these remarkable pumps and explore their remarkable capabilities.

Benefits of Submersible Pumps

Submersible pumps offer numerous advantages in various applications. Here are three key benefits of using these innovative pumps:

Efficient and Reliable Operation:

Submersible pumps are designed to operate underwater, allowing them to effectively pump fluids without the need for priming. Their direct immersion in liquids ensures efficient fluid transfer, eliminating the risk of cavitation that could affect the performance of traditional pumps. With the ability to handle high pressures and large volumes, submersible pumps provide reliable and continuous operation, enhancing productivity in various industries.Space-Saving Design:

One notable advantage of submersible pumps is their space-saving design. Unlike surface pumps that require additional floor space for installation, submersible pumps are installed directly in fluid sources such as wells or sumps. This compact design not only saves valuable space but also reduces the installation and maintenance costs associated with lengthy pipelines and dedicated pump rooms. By taking advantage of underwater placement, submersible pumps offer a practical and efficient solution for limited spaces.Enhanced Durability and Flexibility:

Submersible pumps are built to withstand harsh and challenging environments. Constructed with durable materials, these pumps are highly resistant to corrosion, abrasion, and wear, ensuring longer service life even when subjected to demanding conditions. Moreover, their submersible nature allows them to operate silently, minimizing noise pollution. The versatility of submersible pumps enables their usage in various applications, including wastewater management, mining, agriculture, and drainage systems.

In conclusion, submersible pumps deliver efficient and reliable performance, offer space-saving advantages, and exhibit enhanced durability and flexibility. These features make them invaluable in a wide range of industries, reducing operational costs and contributing to increased productivity.

Advancements in Submersible Pump Technology

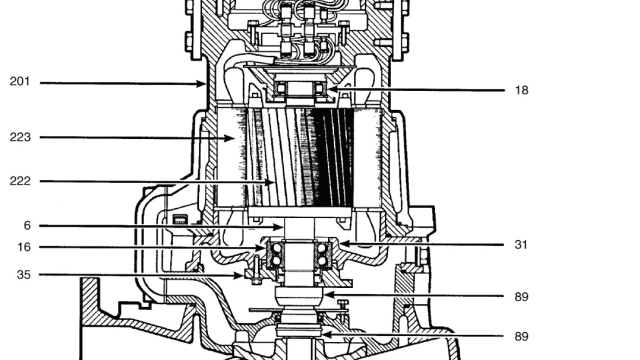

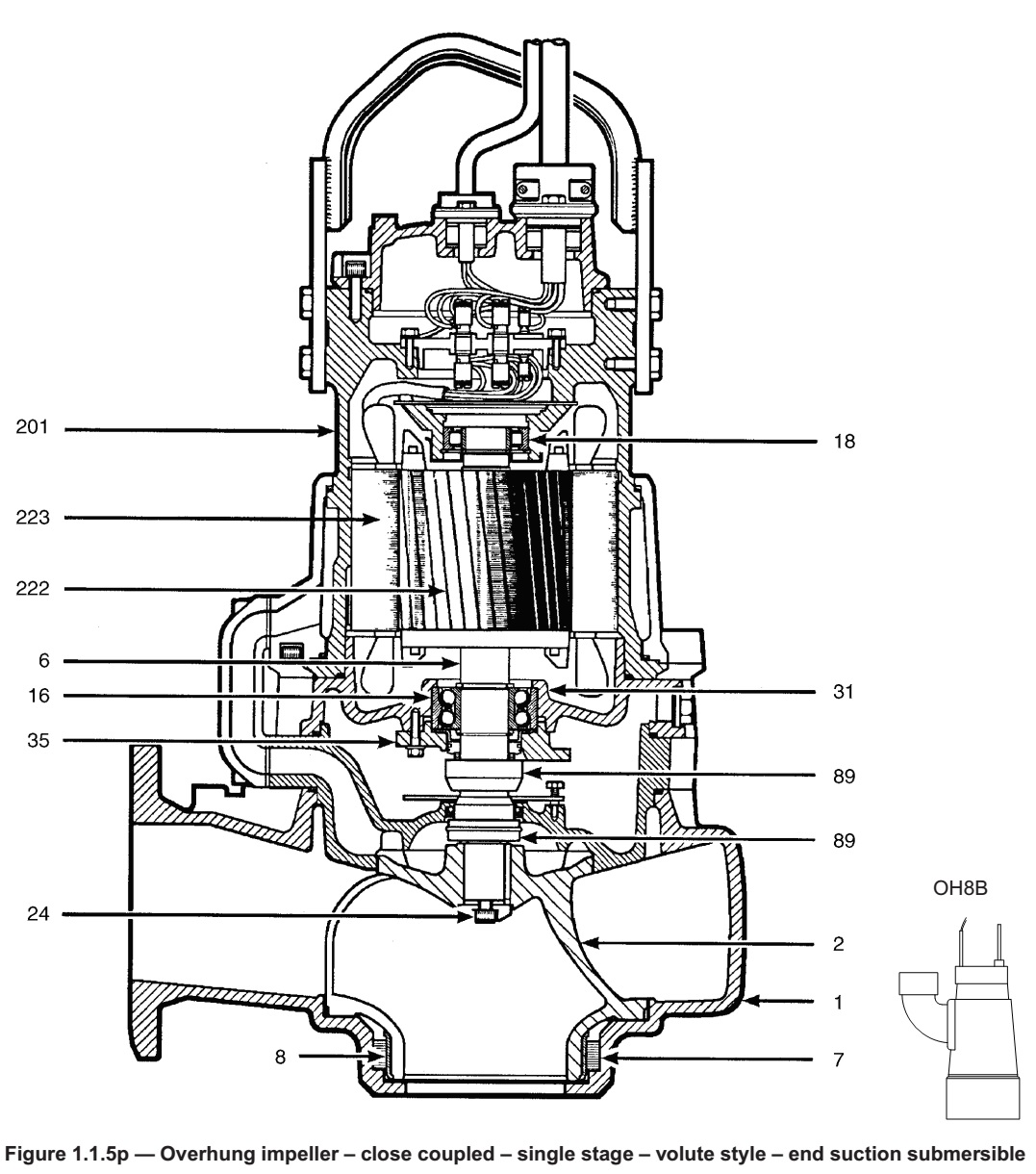

Submersible pumps have undergone significant technological advancements in recent years, revolutionizing various industries that rely on their efficient operation. These pumps, known for their ability to work underwater, have evolved to provide greater performance, durability, and versatility. Let’s explore some of the key advancements in submersible pump technology.

Enhanced Efficiency: One notable advancement in submersible pump technology is the development of more efficient systems. Manufacturers continuously strive to improve the hydraulic design and motor efficiency of these pumps, resulting in increased overall performance. With improved efficiency, submersible pumps can effectively handle a wide range of fluids, including slurries, sewage, wastewater, and even corrosive chemicals.

Durability and Reliability: Another significant advancement in submersible pump technology is the enhancement of their durability and reliability. Manufacturers are constantly exploring new materials and engineering techniques to create pumps that can withstand harsh operating conditions. This includes the use of corrosion-resistant materials, reinforced construction, and innovative sealing mechanisms, ensuring prolonged pump life and minimal downtime.

Intelligent Control and Monitoring: The integration of intelligent control and monitoring systems is a notable breakthrough in submersible pump technology. With the use of advanced sensors and automation, these pumps can now be remotely controlled and monitored. Operators can easily manage and regulate various pumping parameters, such as flow rate, pressure, and temperature, from a centralized control panel or even through mobile applications. This technological advancement enables improved efficiency, predictive maintenance, and real-time troubleshooting, thereby reducing operational costs and maximizing productivity.

These advancements in submersible pump technology have revolutionized various industries, including mining, agriculture, construction, and wastewater management. With their improved efficiency, enhanced durability, and intelligent control systems, these pumps have become indispensable tools for tackling complex pumping challenges. The continuous innovation and development in submersible pump technology are set to further transform the industry, making them even more reliable, efficient, and adaptable to diverse applications.

Applications of Heavy-Duty Submersible Pumps

Heavy-duty submersible pumps have a wide range of applications, making them an essential tool in various industries. They are designed to handle demanding tasks efficiently and effectively. Let’s explore some of the key applications where these pumps excel:

Mining and Construction: Heavy-duty submersible pumps play a vital role in the mining and construction industry. They are used for dewatering mines, quarries, and tunnels, removing excess water from these areas to ensure a safe and productive environment for workers. These pumps can handle high volumes of water and even slurries with ease, making them indispensable in mining and construction operations.

Wastewater and Sewage Treatment: Submersible pumps are extensively used in wastewater and sewage treatment plants. They are responsible for pumping and transferring large volumes of wastewater, sludge, and sewage efficiently. These pumps are designed to handle solids and debris, ensuring smooth and uninterrupted operation within the treatment facilities.

Marine and Offshore Applications: Heavy-duty submersible pumps are prominently used in marine and offshore applications. They serve multiple purposes, such as draining water from dockyards, pumping out floodwater from ships, and facilitating offshore construction projects. These pumps can withstand the harsh marine environment and provide efficient water management solutions.

Mining Sand Dredge

In conclusion, the versatile nature of heavy-duty submersible pumps makes them invaluable in a wide range of applications. Their ability to handle challenging tasks, such as pumping slurry and debris-laden water, makes them a preferred choice in the mining, construction, wastewater treatment, and marine industries.